Aquarium Plumbing Basics: Manifolds, Bypasses & Ball Valves

At

MarineandReef.com customers often ask us how to plumb a new piece of equipment such as a media reactor, polishing filter, UV sterilizer, chiller or inline heater. While you can always use a dedicated pump for every piece of equipment, there are also a couple of ways to use your main system pump to power your equipment.

Manifolds

With a manifold you can use your main return pump from a sump style filter to power extra equipment in your tank. Manifolds work well when you want to divert water to a media reactor in a sump and the water is flowing back into the sump. It is best to plumb the manifold into your system even before you need extra equipment.

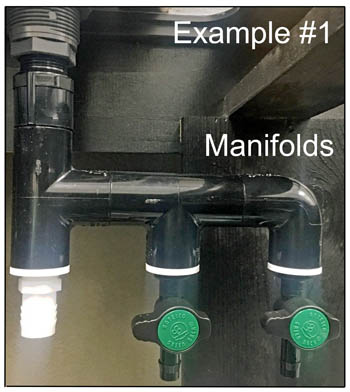

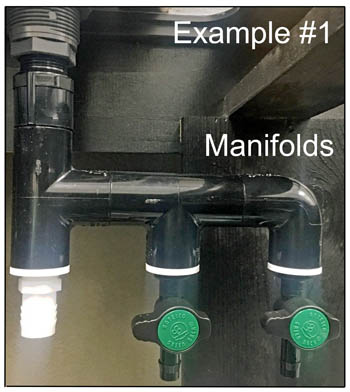

You can see in Example #1 what a basic manifold looks like*. In this example the return hose from the sump connects to the white nylon fitting in the bottom left of the picture. The water returning to the tank goes strait up and then out the return nozzles, and the valves on the right can be used to bleed off some of the water and feed other equipment. If the equipment attached to the ball valves is not in use, you can close them and direct all of the water to the main tank.

The advantage of this setup is you have fewer pumps using power, making noise, producing heat, and requiring maintenance. Because you will use up some of the pump flow, it is a good idea to go one size larger on your return pump than you usually would so that you have enough flow for both the return and the attached equipment.

The two biggest disadvantages of using a manifold to power equipment is that you lose flow from your main return pump, and it only works well if you have a sump style filter.

*We created the manifold from two Schedule 40 PVC Tees and an Schedule 40 PVC Elbow glued together with pvc glue. We used Two Little Fishies Ball Valves.

Bypasses

Bypasses are very useful for diverting some water flow to a UV, chiller, in line heater or polishing filter. A bypass does just what its name suggests—it directs some water through a piece of equipment and some around it. With a bypass you will not lose as much water flow as with a manifold,

If you use ball valves with your bypass you can easily remove the connected equipment for replacement or service without turning off your main pump. This way your aquarium still has water flow.

In Example #2 you can see a UV sterilizer plumbed using a bypass. In this configuration water splits into two lines—one line with the UV and valves on either end, and one line with only a single valve.

With a bypass you can control the flow. This can be very important when using a piece of equipment such a UV sterilizer that requires somewhat exact flow rates. The UV in the picture will only be effective if the flow rate is no more than 200 gallons per hour. But it’s being connected to a filter that is pumping 600 gallons per hour. By splitting the line in two only about half the water passes through the UV. This is still 300 gallons per hour, which is more than the sterilizer can handle, but if you turn one of the ball valves on either end of the UV a quarter turn less water will flow through the UV, and the UV will get the low flow rate it needs.

When it comes time to clean the UV you simple close the ball valves before and after the unit and then remove it for cleaning. No need to turn off the pump while you service the sterilizer. If the unit needed 400 gallons per hour instead of 200 then you could keep the valves before and after the UV open and turn the single valve on the other line by a quarter turn to send most of the water through the UV with only some flowing through the other line.

With a manifold you can use your main return pump from a sump style filter to power extra equipment in your tank. Manifolds work well when you want to divert water to a media reactor in a sump and the water is flowing back into the sump. It is best to plumb the manifold into your system even before you need extra equipment.

With a manifold you can use your main return pump from a sump style filter to power extra equipment in your tank. Manifolds work well when you want to divert water to a media reactor in a sump and the water is flowing back into the sump. It is best to plumb the manifold into your system even before you need extra equipment.